This is a solid modeling method that is used for creating lithology solid models in the Borehole Manager. This technique is also available for downhole quantitative data (e.g. I-data, T-Data, P-data) to provide a means for creating models of data that are horizontally contiguous but numerically discrete. This was previously called "horizontal lithoblending."

The Lateral Extrusion method assigns the solid model voxel nodes using the closest lateral point. It looks outward horizontally from each data point, in search circles of ever-increasing diameter. It first assigns the voxels immediately surrounding each borehole the closest lithology or real number value. It then moves out by a voxel, and assigns the next "circle" of voxels the closest lithology value. It continues in this manner until it reaches the midpoint between the neighboring data point, or until a maximum distance is reached.

For lithology data, the numeric values assigned to each material in the Lithology Types Table are extruded outward from the boreholes into the 3D space of the model.

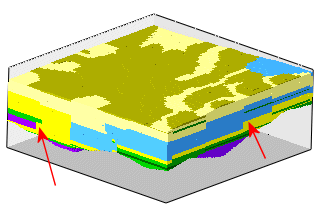

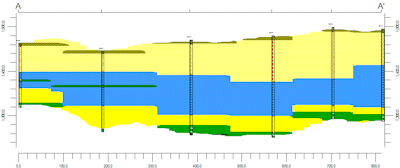

Unlike the Lateral Blending method, the Lateral Extrusion method can create abrupt changes at the borehole midpoints, as shown by the arrows in the above image, and in the cross section below.

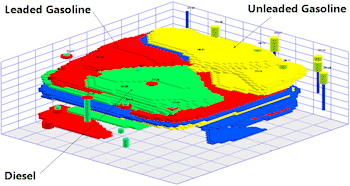

For quantitative data, the lateral extrusion algorithm will conceptually "bleed" measured values outward from the boreholes outwards, coalescing with the adjacent boreholes, without creating gradations. The example below illustrates LIF (Laser Induced Fluorescence) measurements for hydrocarbons in which the data consists of discrete values (e.g. 0.0 = uncontaminated, 1.0 leaded gasoline, 2.0 = unleaded gasoline, and 3.0 = diesel).

![]() Back to Solid Modeling Method Summary

Back to Solid Modeling Method Summary